Test Methods for Coating Adhesion

Ever applied a perfect coating only to watch it flake off at the first sign of stress? You’re not alone. In a recent study, 82% of coating failures were directly attributed to poor adhesion testing protocols.

The difference between a coating that lasts decades and one that fails prematurely often comes down to how thoroughly you test coating adhesion before full deployment.

Let’s cut through the noise. Whether you’re working with metal substrates, plastics, or composites, understanding the right test methods for coating adhesion isn’t just technical busywork—it’s your insurance policy against costly failures.

What if I told you there’s a systematic approach to adhesion testing that virtually eliminates guesswork?

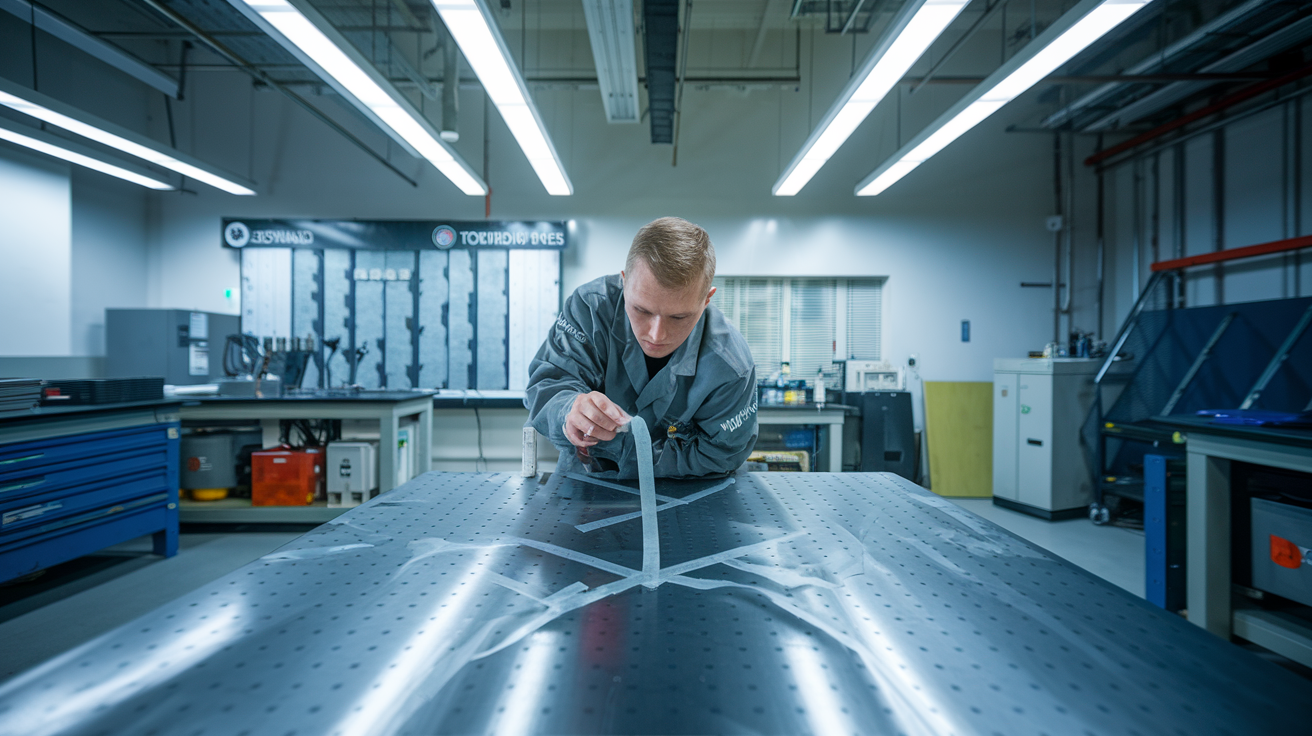

What is a Knife Test?

What is a Knife Test?

The knife test is one of the most straightforward methods for checking coating adhesion. It’s exactly what it sounds like – you use a knife to evaluate how well a coating sticks to its substrate.

Here’s how it works: Take a sharp utility knife and make two cuts through the coating in an “X” pattern. Then try to lift the coating at the intersection using the knife tip. Simple, right?

What makes this test valuable is its directness. You’re physically challenging the bond between coating and substrate, which tells you a lot about real-world performance.

The results are pretty easy to interpret too:

-

If large pieces flake off easily, you’ve got poor adhesion

-

If you can only remove small flakes with significant effort, adhesion is good

-

If you can’t lift anything at all, congratulations – you’ve got excellent adhesion

This test isn’t exactly high-tech, but that’s part of its charm. You don’t need fancy equipment or extensive training. Just a knife and a steady hand.

Many coating professionals rely on this method for quick field assessments. When you’re on a job site and need immediate feedback, the knife test delivers reliable results without the fuss.

The test works on virtually any coating system – industrial paints, protective finishes, even decorative coatings. Just be careful with thin films where the knife might damage the substrate and give you misleading results.

What is a Tape Test?

A tape test is the most common and straightforward method for evaluating coating adhesion. Think of it as the workhorse of adhesion testing – simple, quick, and surprisingly effective.

The process is beautifully uncomplicated: you apply pressure-sensitive tape to a coated surface (sometimes after creating a grid pattern of cuts), then yank it off at a specific angle and rate. The amount of coating that comes off with the tape tells you how well your coating is sticking.

Standard Test Methods

The most widely used tape test procedures come from ASTM International:

-

ASTM D3359: This method uses either an X-cut (Method A) or a cross-hatch pattern (Method B) before applying and removing the tape

-

ASTM D6677: Similar to D3359 but with a more detailed rating system

Why Use Tape Tests?

Tape tests shine because they’re:

-

Incredibly cost-effective

-

Require minimal equipment

-

Can be performed right in the field

-

Give quick, visual results

But they’re not perfect. The results can vary based on who’s doing the test, the specific tape used, and even the temperature and humidity conditions.

Interpreting Results

Results are typically rated on a 0-5 scale:

| Rating | Description |

|---|---|

| 5 | No peeling or removal |

| 4 | Trace peeling along cuts |

| 3 | Jagged removal along cuts up to 1/16 inch |

| 2 | Jagged removal along cuts up to 1/8 inch |

| 1 | Removal from most of grid area |

| 0 | Removal beyond the grid area |

While not as quantitative as some other methods, tape tests remain the go-to first step in coating evaluation because they’re practical and provide immediate feedback on adhesion quality.

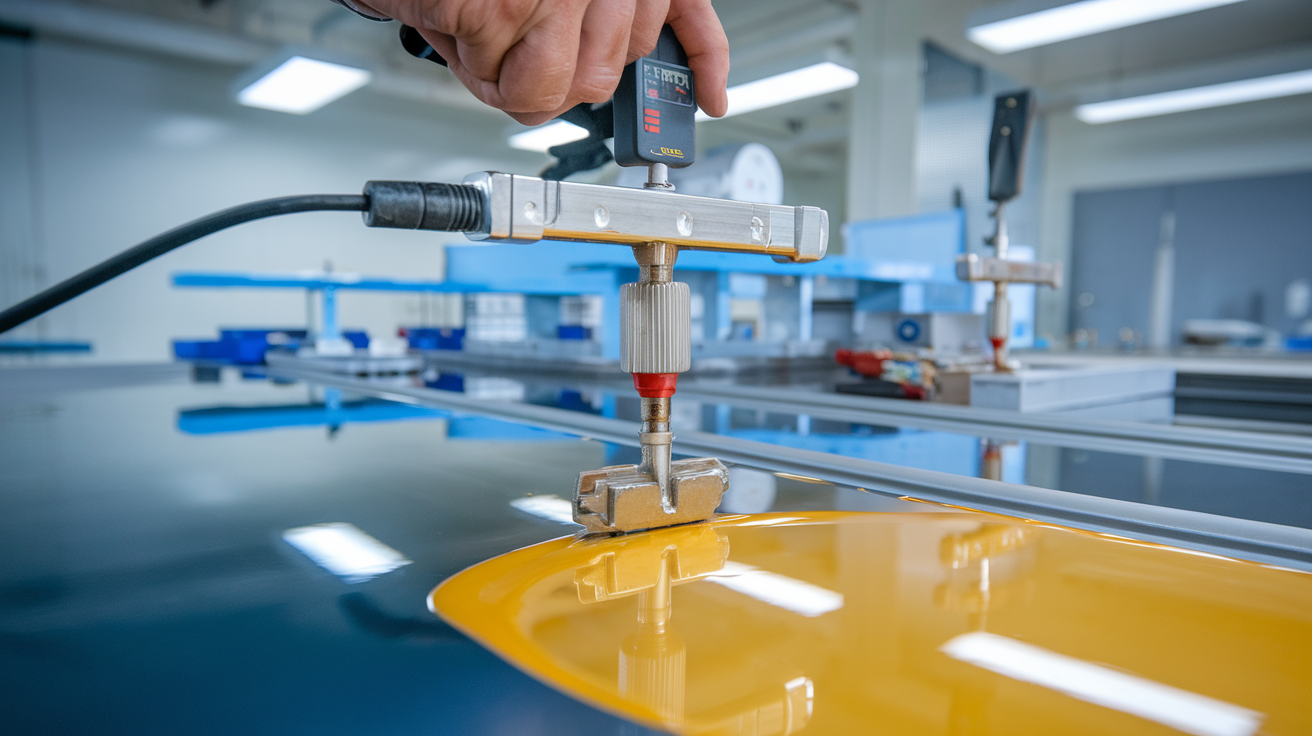

What is a Pull-Off Adhesion Test?

A pull-off adhesion test is exactly what it sounds like – we’re literally pulling the coating off a surface to see how well it sticks. It’s one of the most quantitative methods available for measuring coating adhesion.

The test uses a device that attaches a loading fixture (sometimes called a dolly or stub) to the coating with adhesive. Once cured, the operator applies increasing perpendicular force until the coating detaches or reaches a specified value. The maximum pressure before failure is recorded in PSI (pounds per square inch) or MPa (megapascals).

Equipment Needed

-

Pull-off adhesion tester

-

Loading fixtures (dollies)

-

Adhesive (typically epoxy)

-

Cutting tool for isolating test area

Test Procedure

-

Select representative test areas

-

Clean the surface of the coating

-

Apply adhesive to the dolly

-

Position the dolly on the coating surface

-

Allow adhesive to cure (typically 24 hours)

-

If required, score around the dolly to isolate the test area

-

Attach the pull-off device to the dolly

-

Apply force at a steady rate until failure

-

Record the maximum force and failure mode

Failure Modes

The real value comes from analyzing how the coating fails:

-

Adhesive failure: Coating detaches cleanly from substrate

-

Cohesive failure: Coating splits within its layers

-

Substrate failure: The substrate material itself breaks

Pull-off testing follows standards like ASTM D4541 and ISO 4624, which provide guidelines for proper execution and interpretation of results.

The beauty of this test is its versatility. It works on virtually any rigid substrate – metal, concrete, wood, plastic – making it invaluable for evaluating coatings across industries from construction to aerospace.

What is a Scrape Test?

A scrape test is exactly what it sounds like—you literally scrape the coating to see how well it sticks. It’s one of the simplest and most direct methods to evaluate coating adhesion in the field.

The basic procedure involves using a tool with a sharp edge—typically a knife, chisel, or specialized scraper—to apply increasing pressure to the coating surface. The goal? To determine at what point the coating gives up and separates from the substrate.

What makes this test stand out is its beautiful simplicity. No fancy equipment needed. Just grab a suitable tool and get to work. This makes it perfect for quick field assessments when you need immediate answers about coating performance.

Here’s how professionals typically perform a scrape test:

-

Select a representative test area

-

Hold the scraping tool at approximately a 45° angle

-

Apply steady, increasing pressure while moving the tool forward

-

Observe where and how the coating fails

-

Rate the adhesion based on the amount of pressure required

The results are pretty straightforward. Strong adhesion means the coating resists scraping or only fails under significant pressure. Poor adhesion? The coating pops right off with minimal effort.

Many industries have standardized this test. For example, ASTM D2197 provides a formal method using a balanced-beam scrape adhesion tester that applies measurable, controlled force.

While not as quantitative as some other methods, the scrape test gives you immediate, visual feedback about coating performance. It’s particularly valuable when you need to quickly assess adhesion strength in the field without lugging around specialized equipment.

Other Adhesion Test Methods

Mechanical Adhesion Tests

Beyond the common tape and pull-off tests, several mechanical methods evaluate coating adhesion by applying physical force to the coating.

The scratch test is straightforward but effective. You drag a stylus or needle across the coating surface under increasing load until the coating fails. The load at failure gives you a quantitative adhesion measurement. This test works great for thin coatings on hard substrates.

Then there’s the bend test. You simply bend a coated panel around mandrels of decreasing diameter until you see cracking or peeling. The smallest diameter without failure indicates your coating’s flexibility and adhesion strength. No fancy equipment needed!

Impact testing throws another variable into the mix. Drop a weight onto your coated sample and check for cracking, chipping, or delamination. This simulates real-world impacts that coatings face in service.

Chemical Resistance Tests

Sometimes adhesion problems only show up when chemicals enter the picture. Water immersion testing reveals weakness in coating adhesion that might take months to appear in service. Submerge your sample and check periodically for blistering or lifting.

Solvent resistance tests work similarly – rub the coating with solvents and look for softening or removal. If your coating stays put, you’ve got good adhesion.

Thermal Testing Methods

Heat cycling puts coatings through repeated temperature changes, stressing the bond between coating and substrate. The differential expansion rates often reveal adhesion weaknesses not visible in room-temperature tests.

Cold impact testing combines low temperatures with impact forces – a brutal combination that quickly exposes poor adhesion in cold environments.

Related Articles

Beyond the Basics: Advanced Coating Adhesion Testing

Looking to dive deeper into coating adhesion testing? These related articles expand on specific test methods, applications, and industries where adhesion testing plays a critical role:

Industry-Specific Applications

-

Automotive Coatings: Weathering the Elements – How automotive manufacturers evaluate coating durability in extreme conditions

-

Marine Coating Adhesion – Special considerations for underwater and salt-exposed surfaces

-

Aerospace Coating Requirements – The rigorous standards that keep aircraft safe

Troubleshooting Common Adhesion Failures

When coatings fail, the culprit often lies in surface preparation, application methods, or environmental factors. Our troubleshooting guide helps identify root causes and prevent costly rework.

New Technologies in Adhesion Testing

Traditional methods are evolving. Discover how digital measurement tools, AI-assisted inspection, and non-destructive testing approaches are revolutionizing quality control processes across industries.

DIY Adhesion Testing for Small Projects

Not every project requires laboratory-grade equipment. Learn simple field tests that provide reliable indicators of coating performance before committing to large-scale applications.

Environmental Factors Affecting Coating Adhesion

Temperature swings, humidity, and UV exposure can dramatically impact adhesion performance. This practical guide helps you plan for environmental challenges from the start.

Choosing the right adhesion test method is crucial for evaluating coating performance and ensuring durability in various applications. From simple field tests like the knife and tape tests to more sophisticated laboratory methods such as pull-off adhesion and scrape tests, each approach offers unique insights into how well a coating adheres to its substrate.

For optimal results, consider combining multiple test methods to gain a comprehensive understanding of coating adhesion properties. Remember that proper surface preparation and application techniques are fundamental to achieving strong adhesion from the start. Implementing regular adhesion testing as part of your quality control process will help prevent coating failures and extend the service life of coated products.