what is a release paper?

Ever torn off that final layer from a sticker and wondered what magic keeps the sticky part from sticking until you want it to? That’s release paper at work, silently making your life easier while staying completely invisible in the process.

By the end of this post, you’ll understand exactly how release paper works in everything from shipping labels to complex industrial applications.

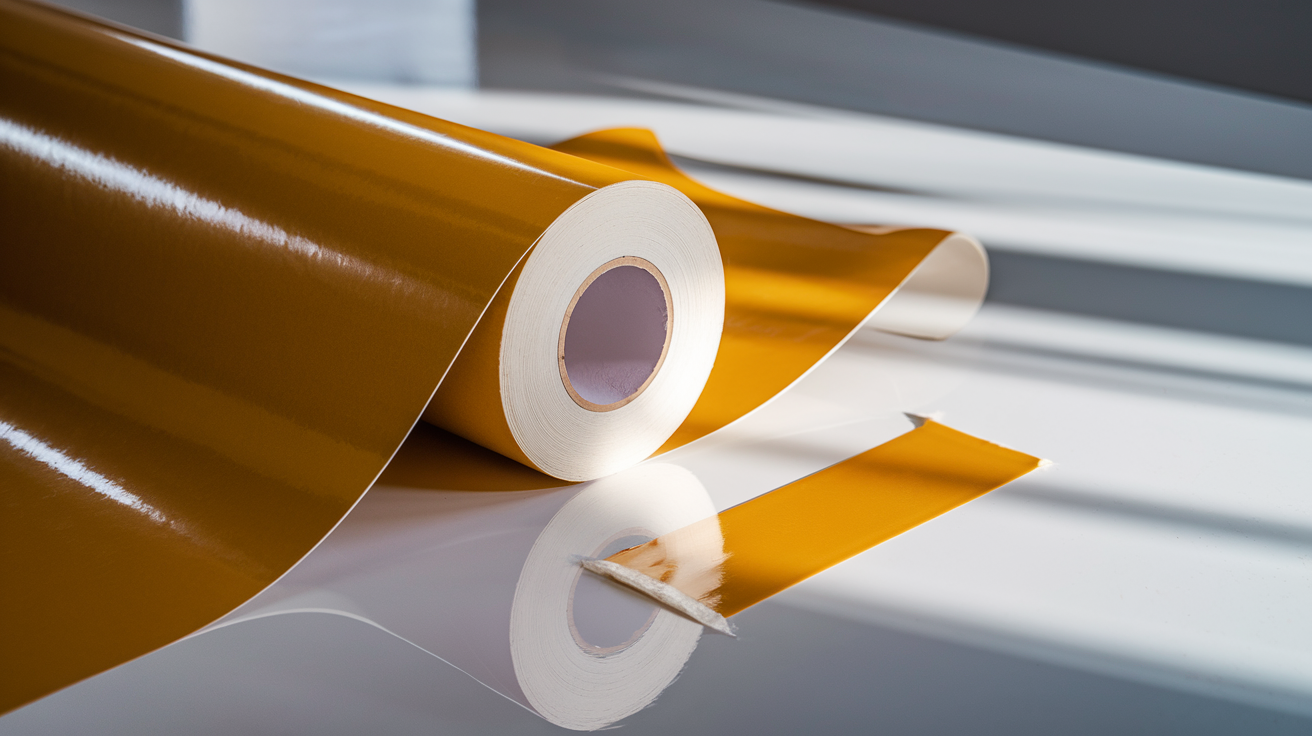

Release paper is essentially the unsung hero of adhesive products, featuring a silicone coating that creates a non-stick surface allowing adhesives to peel away cleanly when needed. It’s why your band-aids don’t stick to their packaging and why shipping labels don’t become permanent fixtures on their backing sheets.

But here’s what most people never consider: the technology behind release papers is far more sophisticated than you might think, and the wrong choice can derail an entire product line…

Understanding Release Paper: The Basics

A. Definition and Core Functions of Release Paper

Release paper is the unsung hero of the adhesive world. Think of it as the protective layer that keeps sticky things from sticking until you’re ready for them to stick. Confusing? Let me break it down.

At its core, release paper (also called release liner) is a specialized paper or film coated with a release agent—typically silicone—that prevents adhesives from permanently bonding to its surface. It’s what you peel off before applying a sticker, label, or adhesive tape.

The main functions of release paper include:

-

Protecting the adhesive layer until use

-

Preventing premature sticking during storage and shipping

-

Enabling easy removal when the adhesive product is ready to be applied

-

Maintaining the adhesive’s tackiness and performance properties

-

Serving as a carrier for die-cutting and converting operations

B. Key Materials Used in Manufacturing Release Paper

The magic of release paper comes down to its construction. Most release papers consist of:

-

Base materials: Usually paper, polyethylene, polypropylene, or polyester films

-

Release coatings: Primarily silicone-based, but can also include chrome complexes, waxes, or fluorochemicals

-

Primers: Applied between the base and release coating to ensure proper adhesion

Premium release papers often use kraft paper, glassine, or clay-coated papers as base materials due to their strength and smooth surface. The thickness typically ranges from 30 to 200 microns, depending on the application.

C. How Release Paper Differs from Standard Paper Types

Regular paper and release paper might look similar at first glance, but they’re worlds apart in function:

| Feature | Standard Paper | Release Paper |

|---|---|---|

| Surface treatment | Minimal or none | Specialized release coating |

| Porosity | Generally higher | Controlled and often lower |

| Tensile strength | Variable | Higher for durability |

| Moisture resistance | Low to moderate | Enhanced |

| Cost | Lower | Higher due to specialized coatings |

The silicone coating is what gives release paper its non-stick properties—something you definitely won’t find in your printer paper or notebook.

D. Common Industry Terms and Terminology

Diving into the world of release paper means getting familiar with some specialized lingo:

-

Release force: The amount of force required to separate the adhesive from the release liner

-

Silicone transfer: Unwanted migration of silicone from the release paper to the adhesive

-

Quick release: Liners designed for easy, low-force removal

-

Tight release: Liners requiring more force to remove, used for high-tack adhesives

-

Double-sided release: Paper treated with release coating on both sides

-

Differential release: When the two sides of a liner have different release properties

These terms help manufacturers and users communicate exactly what properties they need in a release paper for specific applications.

Types of Release Paper in Today’s Market

Types of Release Paper in Today’s Market

A. Silicone-Coated Release Papers

The heavyweight champion of release papers is definitely silicone-coated. These papers dominate the market for good reason. The silicone coating creates an ultra-smooth surface that allows adhesives to peel away cleanly without leaving residue behind.

Companies love silicone-coated release papers because they work with practically any adhesive system. The release force (how hard you need to pull) can be customized from super easy to more controlled release. This flexibility makes them perfect for everything from simple labels to complex medical applications.

What makes them special? The silicone forms a non-stick barrier that’s chemically inert, temperature resistant, and incredibly stable over time. You’ll find these papers backing adhesive tapes, graphic arts materials, and composite manufacturing.

B. Clay-Coated Release Papers

Clay-coated options offer a different approach. These papers have a mineral coating that creates a smooth, dense surface perfect for applications needing precise texture transfer.

The synthetic clay minerals give these papers excellent dimensional stability and moisture resistance. That’s why they’re the go-to choice for artificial leather manufacturing, decorative laminates, and textured surfaces.

Clay-coated release papers shine when you need to transfer a specific pattern or texture to another material. The clay coating accepts detailed embossing patterns that can then be perfectly transferred to your end product.

C. Polyethylene-Coated Options

When you need serious durability and moisture resistance, polyethylene-coated release papers step into the spotlight. These papers feature a thin film of polyethylene that creates a waterproof barrier.

The plastic coating makes these papers incredibly tough against tears, punctures, and environmental factors. They’re the workhorses of release papers – able to handle rough processing conditions without breaking down.

Manufacturers choose polyethylene-coated papers for applications involving water-based adhesives, outdoor exposure, or high-humidity environments. The coating prevents moisture from penetrating the paper base, keeping it dimensionally stable even in challenging conditions.

D. Specialty and Custom Release Papers

Some applications demand something beyond standard options. That’s where specialty and custom release papers come in.

These papers can feature multi-layer coatings, unique surface textures, or specialized chemical treatments. For example, fluorosilicone-coated papers can release even the most aggressive silicone adhesives – something standard release papers struggle with.

Custom papers might include embedded security features, color-changing indicators, or proprietary surface treatments developed for specific manufacturing processes.

The beauty of specialty papers is their precision engineering for exact performance requirements. When standard papers just won’t cut it, these tailored solutions save the day.

E. Eco-Friendly and Sustainable Alternatives

The release paper industry isn’t immune to the sustainability revolution. Eco-friendly alternatives are gaining serious traction.

Today’s green options include papers made from recycled content, papers using water-based coating systems instead of solvent-based ones, and papers designed for easier recycling after use.

Some manufacturers have developed biodegradable release papers using plant-based polymers for the release coating. Others focus on reducing the environmental footprint of traditional silicone coatings through improved manufacturing processes.

The most innovative sustainable papers maintain performance while reducing environmental impact – no small feat considering the technical demands placed on release papers.

Primary Applications and Uses

A. Adhesive Product Manufacturing

Release paper is the unsung hero in the adhesive world. Without it, your sticky labels would be a nightmare to handle. It’s that backing material that keeps the adhesive from sticking to everything before you’re ready to use it.

In manufacturing, release papers serve as temporary carriers during production. Think about it – how else would companies mass-produce sticky tapes, bandages, or stickers? The release paper holds the adhesive layer in place throughout the entire manufacturing process.

What makes release paper so valuable is its controlled release properties. Manufacturers can fine-tune exactly how easily the adhesive product peels away. Too loose, and products fall off during shipping. Too tight, and end-users curse while struggling to remove it.

Many adhesive manufacturers rely on silicone-coated release papers because silicone creates that perfect non-stick surface without damaging the adhesive properties.

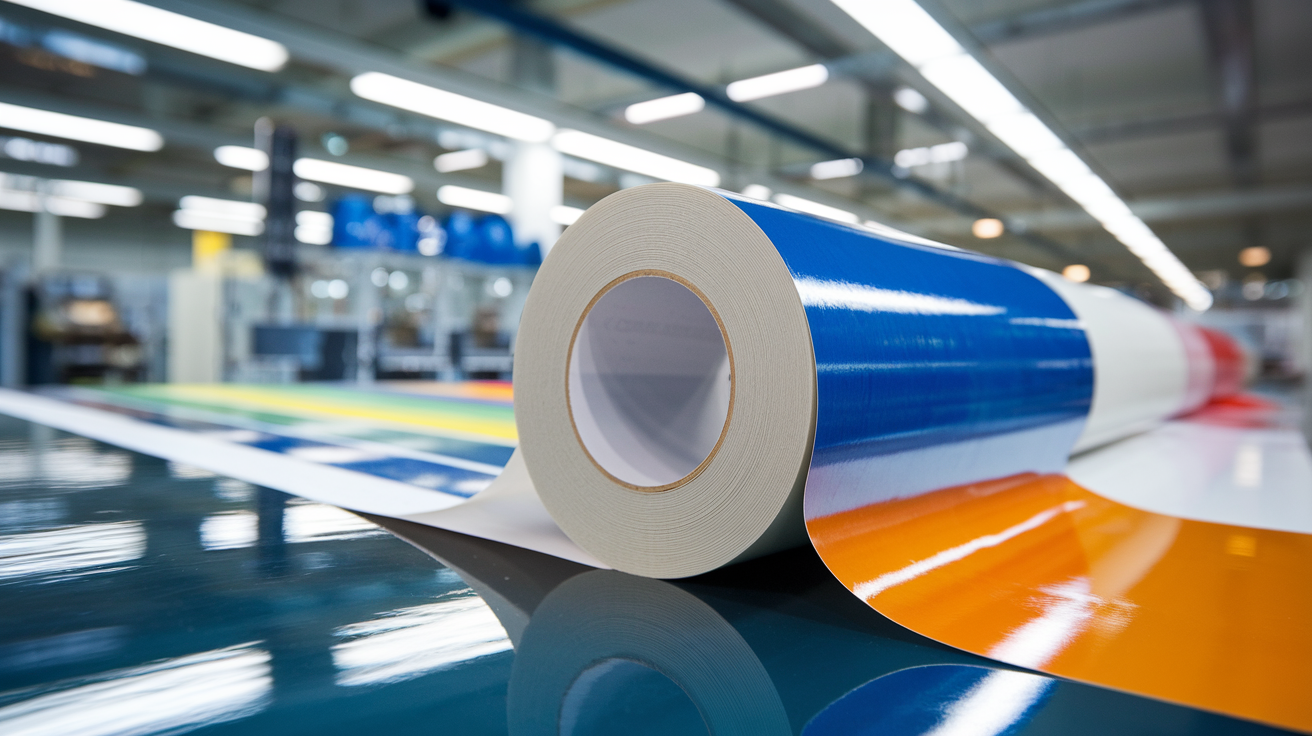

B. Label Production and Sticker Making

Walk into any office or retail store and you’ll find labels everywhere. Price tags, shipping labels, product stickers – all rely on release paper.

The label industry would collapse without quality release papers. They’re the base that carries the face stock (the actual label) and the adhesive until it’s time for application.

Release papers for labels come in different strengths:

-

Light-release: For large labels that need to come off easily

-

Medium-release: The all-purpose option for most label applications

-

Tight-release: When labels need to stay put during processing

Die-cutting operations (where labels are cut into specific shapes) depend on release papers that maintain their integrity even when cut, sliced, and processed at high speeds.

C. Composite Material Fabrication

Composite materials are everywhere – from airplane parts to kitchen countertops. And guess what? Release paper plays a crucial role in making them.

During the manufacturing of fiber-reinforced composites, release papers serve as separation layers between the composite material and molding tools. This prevents the resins from bonding to expensive molds and tooling.

The aerospace industry depends on specialized high-temperature release papers that can withstand the intense heat of curing processes for carbon fiber components.

For decorative laminates used in furniture and countertops, release papers with textured surfaces can even impart specific patterns and finishes to the final product.

D. Medical and Hygiene Product Applications

The medical industry has some of the most demanding standards for release papers. Think about it – these materials come in direct contact with products that touch your skin or even enter your body.

Wound dressings, surgical tapes, and transdermal patches all require medical-grade release papers that are:

-

Free from contaminants

-

Produced in clean-room environments

-

Tested for biocompatibility

In hygiene products like sanitary pads and diapers, release papers protect adhesive strips until the product is ready for use.

The requirements here are particularly strict – the release paper must maintain its properties through sterilization processes and long shelf storage, while remaining safe for human contact.

Technical Properties of Quality Release Paper

A. Release Force and Its Importance

Ever tried peeling a sticker and it either tore apart or left stubborn residue behind? That’s all about release force—the key factor that makes or breaks a good release paper.

Release force is the amount of effort needed to separate the adhesive material from the release paper. Think of it as the “peel strength.” Too high, and you’ll damage the adhesive material during removal. Too low, and premature separation might occur during processing or storage.

Most manufacturers measure release force in grams per inch (g/in) or Newton per meter (N/m). The sweet spot depends entirely on your application:

| Application | Typical Release Force | Why It Matters |

|---|---|---|

| Label stock | 20-40 g/in | Ensures automated dispensing works smoothly |

| Medical tape | 10-25 g/in | Allows gentle removal from packaging |

| Industrial tapes | 50-100+ g/in | Prevents unwanted release during processing |

What many people don’t realize is that release force isn’t static—it changes with peel speed, angle, and temperature. A quality release paper maintains consistent release properties across various conditions.

Smart manufacturers actually custom-engineer release forces for specific applications. Some even create differential release papers with varying release forces on different sides or areas of the same sheet—pretty clever for complex applications!

B. Heat and Chemical Resistance Features

The durability of release papers under harsh conditions is what separates the pros from the amateurs.

Heat resistance is non-negotiable for release papers used in high-temperature applications. Quality release papers maintain their release properties between -40°F to 400°F (-40°C to 204°C), depending on their formulation. This matters tremendously in hot melt adhesive applications or heat curing processes where regular papers would simply break down.

Chemical resistance is equally critical. Premium release papers stand up to:

-

Solvents in adhesive formulations

-

Oils and greases in industrial settings

-

Moisture during processing and storage

-

UV exposure during outdoor applications

The silicone coating (or alternative release agent) provides this resistance. Its cross-linked structure creates a barrier that protects both the paper substrate and maintains release properties when exposed to chemicals.

I’ve seen manufacturers ruined by skimping on heat and chemical resistance testing. Nothing’s worse than discovering your release paper degrades halfway through a production run, contaminating your adhesive product and costing thousands in downtime.

Modern release papers often incorporate specialized additives that enhance resistance properties for specific environments—fluorochemicals for oil resistance or UV stabilizers for outdoor applications.

C. Dimensional Stability Benefits

Dimensional stability might sound boring, but it’s the unsung hero of release paper performance.

Simply put, dimensional stability is a release paper’s ability to maintain its shape and size under changing conditions. When a release paper warps, shrinks, or expands, it creates major headaches:

-

Misregistration in printing and die-cutting

-

Wrinkles and bubbles in lamination

-

Adhesive oozing beyond intended areas

-

Web breaks in high-speed converting lines

What affects dimensional stability? Mainly moisture and temperature fluctuations. Quality release papers use base stocks with controlled fiber orientation and sophisticated calendering processes to minimize these issues.

The benefit? Precision. When you’re working with tight tolerances in electronics, medical devices, or automotive applications, dimensional stability means reliable product quality.

Here’s what makes a dimensionally stable release paper:

-

Base paper with balanced machine and cross-direction properties

-

Proper sizing agents to control moisture absorption

-

Adequate calendering to create uniform density

-

Controlled coating weight distribution

Manufacturers that value precision choose release papers with guaranteed dimensional stability specifications—typically expressed as percentage change under standard testing conditions.

D. Shelf Life and Storage Considerations

The clock starts ticking on release paper performance the moment it leaves the factory.

Quality release papers typically offer shelf lives between 6 months to 2 years—but that’s only under proper storage conditions. Store them wrong, and performance degrades rapidly.

The biggest shelf life killers:

-

Humidity fluctuations (causing curl and dimensional changes)

-

Temperature extremes (affecting release coating properties)

-

Pressure (blocking or transfer of silicone to adjacent layers)

-

Light exposure (particularly UV, which degrades certain coatings)

Smart manufacturers store release papers in climate-controlled environments at 65-75°F (18-24°C) with 40-60% relative humidity. Always keep them in original packaging until use, and store rolls horizontally to prevent edge damage.

Some advanced release papers now come with shelf-life indicators that change color when the product approaches expiration. Others feature specialized packaging with moisture barriers and UV protection.

The release force typically increases over time—a phenomenon called “aging.” Quality release papers are designed with this in mind, starting with slightly lower initial release values to accommodate the expected increase during shelf life.

Proper rotation of inventory (first in, first out) prevents unexpected performance issues from expired materials hitting your production line.

Selecting the Right Release Paper for Your Needs

Essential Factors to Consider Before Purchasing

Choosing the right release paper isn’t just about grabbing whatever’s available. You need to think about several key factors that’ll make or break your project.

First up, the release force. This determines how easily the adhesive separates from the paper. Too high? Your adhesive might damage during removal. Too low? It might detach prematurely.

Surface smoothness matters big time. Rougher release papers transfer their texture to adhesives, while ultra-smooth options create glossy finishes.

Don’t forget about temperature resistance. If your application involves heat (like hot-melt adhesives), you’ll need release paper that won’t degrade at higher temperatures.

Moisture resistance is critical too. Some applications expose release paper to humidity or water, requiring options with proper moisture barriers.

Thickness and rigidity affect handling. Thinner papers offer better conformability but less durability, while thicker ones provide stability but less flexibility.

Chemical compatibility is non-negotiable. Your release paper must resist any solvents or chemicals in your adhesive system.

Industry-Specific Requirements and Standards

Different industries have wildly different needs when it comes to release paper.

Medical applications demand sterilizable release papers that meet strict FDA regulations. These papers can’t contaminate adhesives used in wound dressings or surgical tapes.

The construction industry needs heavy-duty release papers that withstand rough handling and varying environmental conditions.

Electronics manufacturing requires release papers with precise thickness control and absolutely zero contaminants that could interfere with sensitive components.

Food packaging has its own set of standards—release papers must comply with food safety regulations and remain stable during processing and storage.

Automotive applications need heat-resistant release papers that perform under extreme temperature variations.

Check industry certifications like ISO standards, FDA approvals, or specific industry protocols before making your choice.

Cost vs. Performance Analysis

The price tag isn’t everything when it comes to release paper. Sometimes the cheapest option costs you more in the long run.

Premium silicone-coated papers might hit your wallet harder initially but often deliver better release consistency and longer shelf life. For high-volume production, this consistency translates to fewer production stops and less waste.

Lower-cost options work perfectly fine for less demanding applications. Why pay premium prices when standard release paper handles the job?

Consider these factors in your cost analysis:

| Factor | Impact on Cost | Performance Consideration |

|---|---|---|

| Coating type | Higher for premium coatings | Better release control, longer shelf life |

| Base paper weight | Heavier = more expensive | Improved handling, less tearing |

| Size requirements | Custom sizes cost more | Reduces waste in production |

| Order volume | Bulk orders = lower unit cost | Storage requirements, shelf life |

| Specialty features | Increases cost | Application-specific benefits |

Your production volume matters too. High-volume operations benefit from premium papers that reduce downtime, while small batch productions might prioritize lower upfront costs.

Working with Release Paper Suppliers

Building a good relationship with suppliers pays off huge dividends. Don’t just order and forget.

Ask for samples before placing large orders. Testing small quantities in your actual production environment helps avoid expensive mistakes.

Many suppliers offer technical support and can recommend specific products for your application. Use their expertise—they’ve seen countless applications and know what works.

Delivery schedule flexibility matters. Can they accommodate rush orders? Do they maintain inventory of your preferred papers? These questions matter when you’re facing tight production deadlines.

Quality consistency varies between suppliers. Some maintain rigorous quality control processes while others… not so much. Request quality certifications and batch testing data.

Consider geographic location too. Local suppliers offer faster delivery and easier communication, while international ones might provide cost advantages or specialty products not available domestically.

Don’t hesitate to negotiate terms for repeat orders. Volume discounts, payment terms, and consistent pricing can significantly impact your bottom line over time.

Innovations and Future Trends

Advancements in Release Coating Technology

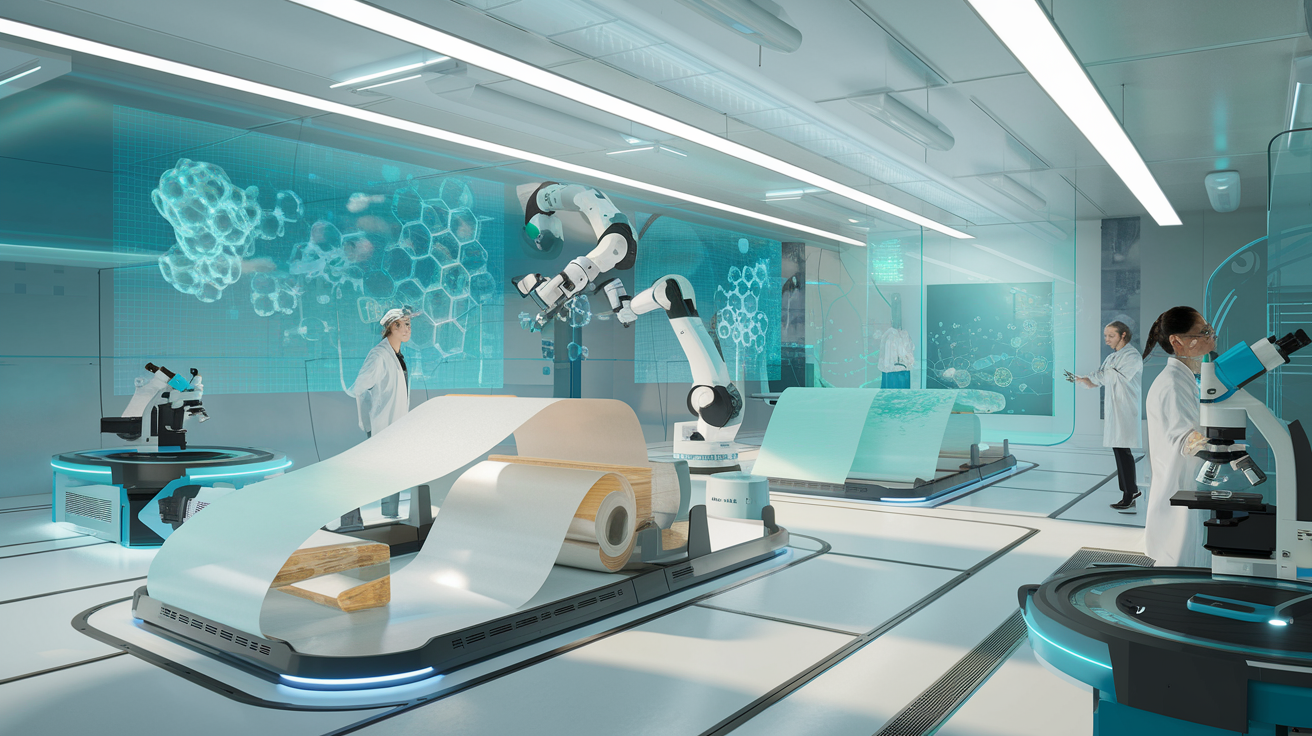

The release paper industry isn’t sitting still. Far from it! Since 2023, we’ve seen remarkable breakthroughs in coating technologies that have transformed what release papers can do.

Nanotechnology has revolutionized release coatings by creating ultra-thin silicone layers that use 40% less material while providing even better release properties. These microscopic wonders allow manufacturers to create coatings with precise control over release forces – something that was merely wishful thinking just a few years ago.

UV-curable coatings have also made huge strides. The latest generation cures in milliseconds, slashing production times and energy costs. A major paper producer in Finland reported energy savings of 65% after switching to these systems in 2024.

Water-based release coatings are finally matching the performance of solvent-based alternatives. This breakthrough came when researchers discovered how to stabilize silicone emulsions at the nano level, preventing the dreaded “orange peel” effect that plagued earlier formulations.

Smart Release Papers with Enhanced Functionality

Smart release papers are no longer science fiction. They’re here, and they’re changing everything.

Temperature-sensitive release papers now dominate certain medical applications. These ingenious materials maintain strong adhesion until exposed to specific temperatures, allowing wound dressings to be removed painlessly.

RFID-embedded release papers are revolutionizing inventory tracking. Imagine release liners that communicate with warehouse systems, reporting their location, quantity, and even application status. Major logistics companies have reported inventory accuracy improvements of over 99% since implementing these systems.

Anti-counterfeiting features integrated directly into release papers now protect luxury brands. These papers contain unique identifiers visible only under specific conditions, making fake products instantly recognizable.

Environmentally Friendly Developments

The sustainability revolution has finally reached release papers, and it’s about time!

Biodegradable release papers made from cellulose derivatives now decompose completely within 12 months in commercial composting facilities. This solves the long-standing problem of release paper waste in landfills.

Recyclable silicone formulations represent perhaps the biggest breakthrough. New silicone chemistry allows the coating to be easily separated from the base paper during recycling processes. The recovered silicone can be reprocessed and used again – a true circular economy solution.

Plant-based release agents derived from renewable resources like algae and agricultural byproducts are replacing petroleum-based chemicals. These bio-alternatives not only reduce carbon footprints but often outperform their fossil-derived counterparts in release consistency and shelf stability.

Solvent-free manufacturing processes have eliminated VOC emissions in modern release paper production. The air quality improvements at manufacturing facilities have been so dramatic that several plants have reported worker respiratory issues dropping to zero.

Mastering Release Paper Selection for Optimal Results

Release paper serves as an essential component in numerous manufacturing processes, acting as the protective barrier that prevents adhesive materials from sticking prematurely. From silicone-coated varieties to fluoropolymer-treated options, the market offers diverse solutions tailored to specific industrial needs. Whether you’re working in label production, composite manufacturing, or medical applications, understanding the technical properties—such as release force, dimensional stability, and temperature resistance—remains crucial for achieving consistent results.

As technology advances, we’re seeing exciting innovations in environmentally friendly release papers, including biodegradable options and solvent-free coatings that maintain performance while reducing ecological impact. When selecting release paper for your next project, carefully assess your specific application requirements, production environment constraints, and sustainability goals. The right choice will not only improve your manufacturing efficiency but also contribute to higher-quality end products and potentially reduce your environmental footprint.